What functions does a feed bunker have?

The purpose of a feed hopper is to

- store material store

- feed

- dosage

- and equalization

of the material in the recycling process.

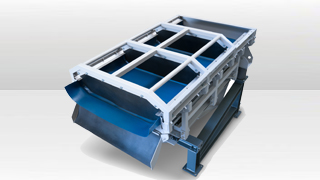

In recycling, the recycled material is prepared for reuse. There are process steps that build on each other. For example, this includes classification and screening using a stationary screening machine or mobile screening plant. NIR sorting and/or magnetic sorting can also be part of the recycling process. The process begins with the feeding of the material.

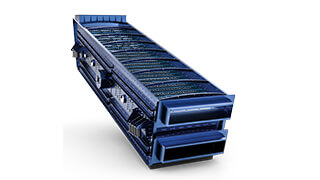

Feed hoppers are used for this purpose. They store the material. This is filled or fed into the feed hopper using a wheel loader, for example. In addition to storing the material, one of the main tasks of the feed hopper is to transfer the material to the downstream machines. The aim is for the feed hopper to feed the material to the treatment process in the desired quantity.

USA

USA