Screening machine manufacturer

As a 5th generation machine manufacturer with decades of experience in the development and manufacture of innovative screening machines, we offer you customized solutions for your screening technology tasks.

innovative

Solutions that get you ahead

CONNECTED

Optimally integrable & powerful technology

Future-proof

Adaptable technology – even when changing materials

Our goal: The best screening results for your recycling project

Leading screening technology for maximum yield

Internationally, we are a strong and reliable partner to the recycling industry. Together with you, we develop screening machines that set new performance standards for your recycling material. We would be pleased to present reference plants to you personally!

Ready for any application

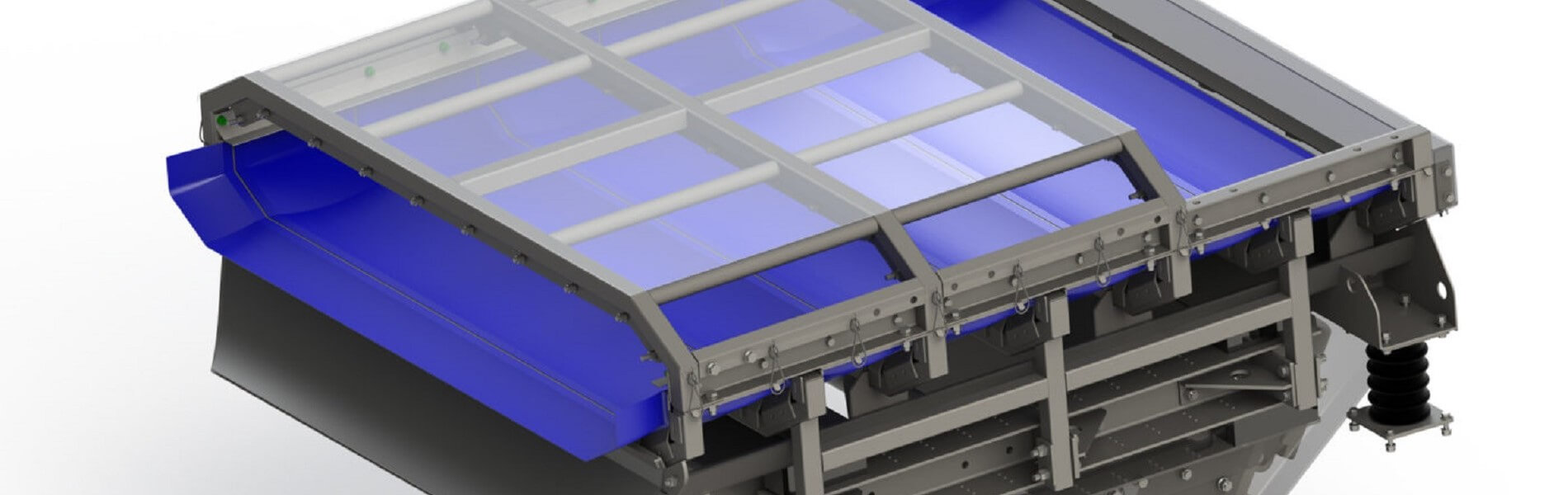

Our ModularDESIGN+ principle

Screening materials can change.

Your SPALECK screening machine can too.

Our solutions offer you maximum performance, reliability and protection of your equipment.

Our ModularDESIGN+ gives you maximum process reliability, even if framework conditions change at a later stage. This is why we build every single SPALECK 100% customised to your current and adaptable to your future recycling applications.

Screening machines for recycling

Why the screening quality is important

Screening machines are indispensable for the recycling process of most recyclable materials. The rule is: the more precise the screening, the better the overall recycling result later on. This is because optimised screening quality enables downstream recycling machines such as magnetic sorters, eddy current devices, X-ray sorters, NIR sorters or wind sifters to process the individual fractions in the best possible way. Screens therefore play an important role in the circular economy in the recovery of recyclable materials and raw materials.

Industrial screening machines

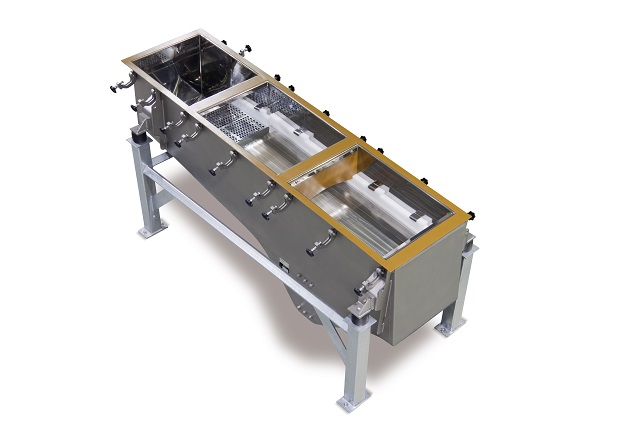

Focus on product safety and quality

In the chemical and food industries, screens are very important for product safety and quality.

In the production of pharmaceuticals, food or chemical products and plastics, the machines often take on the function of control screening, dewatering or the separation of oversized parts They are also used for dosing.

You can find screening machines, feeders and dosing units for pharmaceutical, chemical and food applications here.

Screening machines for pharmaceutical, food and chemical applications

Quality

to the smallest detail

Made in Germany since 1869

We have been building machines for more than 150 years.

You can rely on this experience.

In the area of screening technology, we produce world-class systems that are successfully used by leading recyclers. You also benefit from our in-house metal processing and manufacturing expertise in the field of precision parts.

Innovations made by SPALECK

Achieving more together

We build the screening machines of tomorrow for you. With a vertical range of manufacture of well over 90% and a highly experienced engineering team, we maximise the performance and efficiency of your screening process.

Leading in recycling

Designed for efficient screening

Your new SPALECK screening machine:

Perfectly matched to your application.

Together with you, we determine the most efficient screen for your recycling process.

Benefit from our expert knowledge and the experience of thousands of successful customer applications.

What is a screening machine?

Screening technology briefly explained

A screening machine is used to separate and classify the material to be screened according to grain size. The aim is to separate the feed material of different sizes into size classifications using screening technology. The screening machine is used to separate the screened material according to size. The screening process is also known as classification or grading. During the screening process, the material is cleanly and reliably separated into the desired screen fractions.

Screening machines are also used for dewatering or for control screening. Typical applications are the classification, control and protection, separation, dewatering and separation of clumps.

The video shows how the screening of household and commercial waste works using an animation. It is very easy to see how the screen deck screens smaller material into different screen sections, while the larger material moves further down the screen surface.

For which materials are screening machines used?

Examples of screenings

There is hardly any (recycling) material that cannot be screened. These include heavy and light materials, large to very small grain sizes, moist and wet materials, as well as dusty or dry screenings.

- Metals

- Shredder light fractions

- Shredder heavy fractions

- Auto shredder residue

- Old tires

- E-Waste

- Biomass

- Batterys

- Fertilisers

- and hundreds of other materials

Basic information

Below you will find answers to basic questions about screening machines. If you have any further questions, our team will be glad to help you!

Below you will find an overview of screening machine types and models

Vibrating screening machines

- Vibrating screens

- Circular vibrating screens

- Elliptical motion screens

- Linear vibrating screens

- Banana screens

- Eccentric screening machines

- Setting machines (often for sand and gravel processing)

Flip-Flow Screening Machines

- Single-deck Flip-Flow Screen

- Double-deck flip-flow screen

Other

- Drum screening machines

- Flat screening machines

- Laboratory sieves

- Centrifugal screening machines

- Tumbler screening machines

- Dewatering screens

- Wet screening machines

Depending on the type of screening machine, there are machines in different sizes.

While GMP-compliant screening machines in food production are generally smaller, we produce our screening machines for recycling in sizes of up to 2×10 m or 3×10 m as standard.

There are also single-deck, double-deck and triple-deck screening machines.

Screening machines are available both as mobile screening plants and as stationary screens.

Screening according to particle size is essential in processing and recycling. This is because the downstream sorting devices can only achieve optimum economic results with very clean fractions.

Depending on the type of screening machine, these are used for

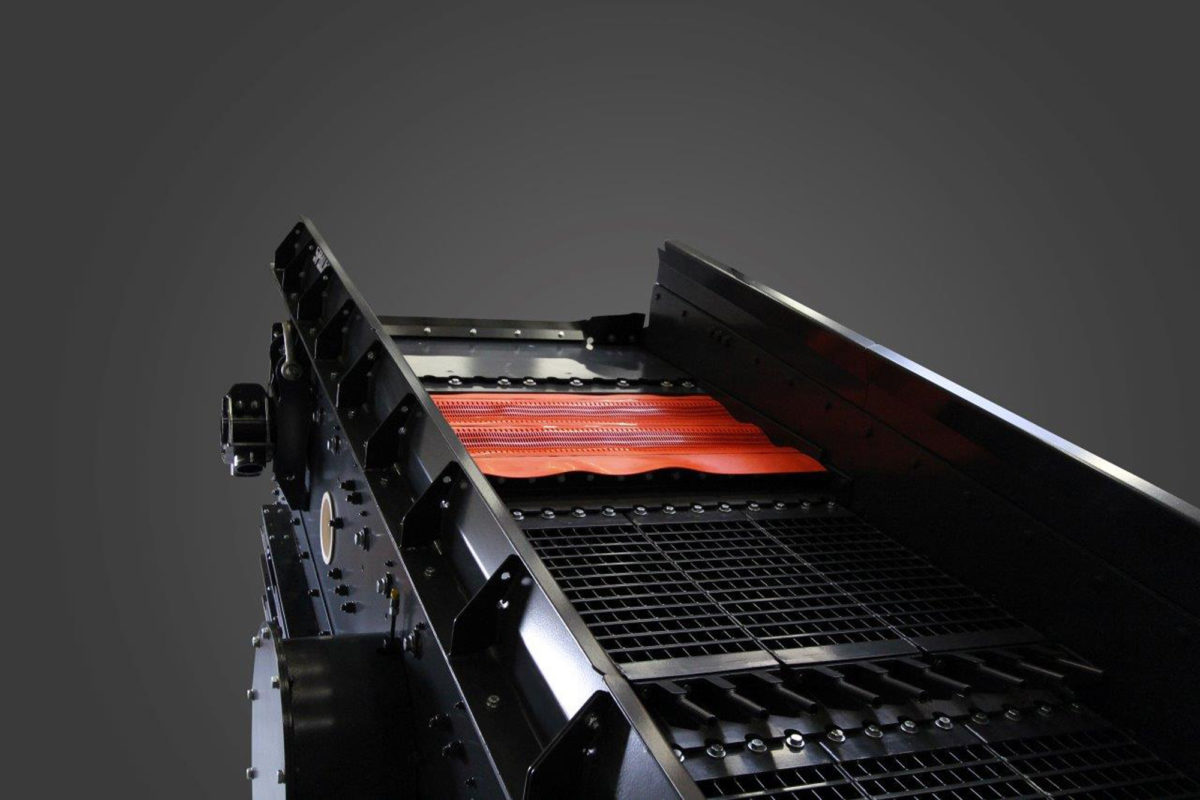

The new ActiveCLEAN

The revolution in slag processing.

One of our latest innovations is revolutionising slag processing. The main benefit for the user:

It is the world’s first cleaning-free, self-cleaning solution.

Also mobile: world class

Screening technology from SPALECK

Achieve maximum screening performance anywhere – of course with screening technology made by SPALECK.

Test the Terex Finlay 883+ SPALECK now – one of the best mobile screening plants in the world.

USA

USA