Open this in UX Builder to add and edit content

SUPPLIER FOR DEFENSE TECHNOLOGY PRODUCTS

When manufacturing or repairing defense technology products for the German Armed Forces by welding, brazing or thermal spraying, companies require an application standard, the so-called DIN 2303.

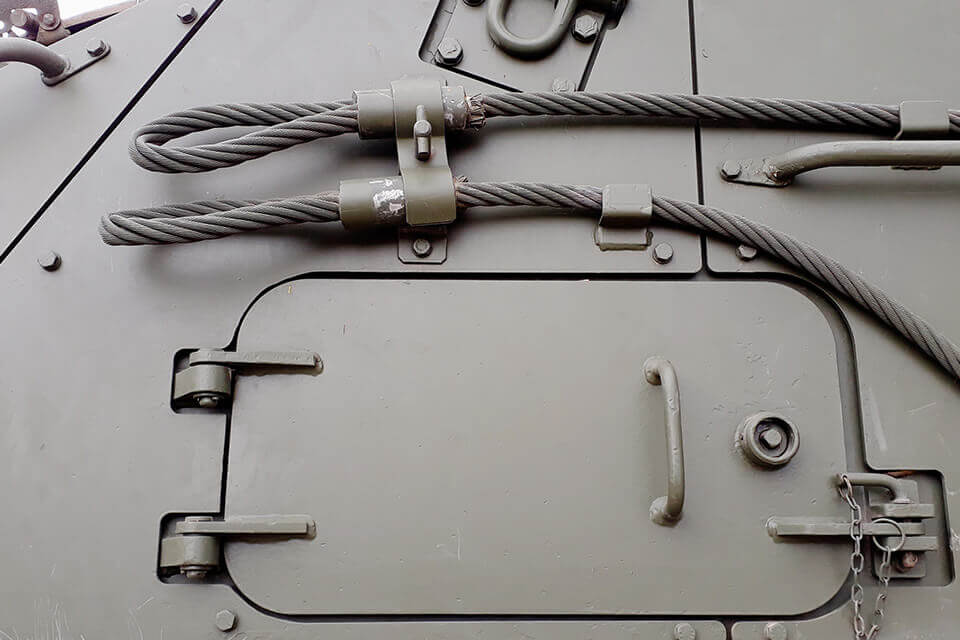

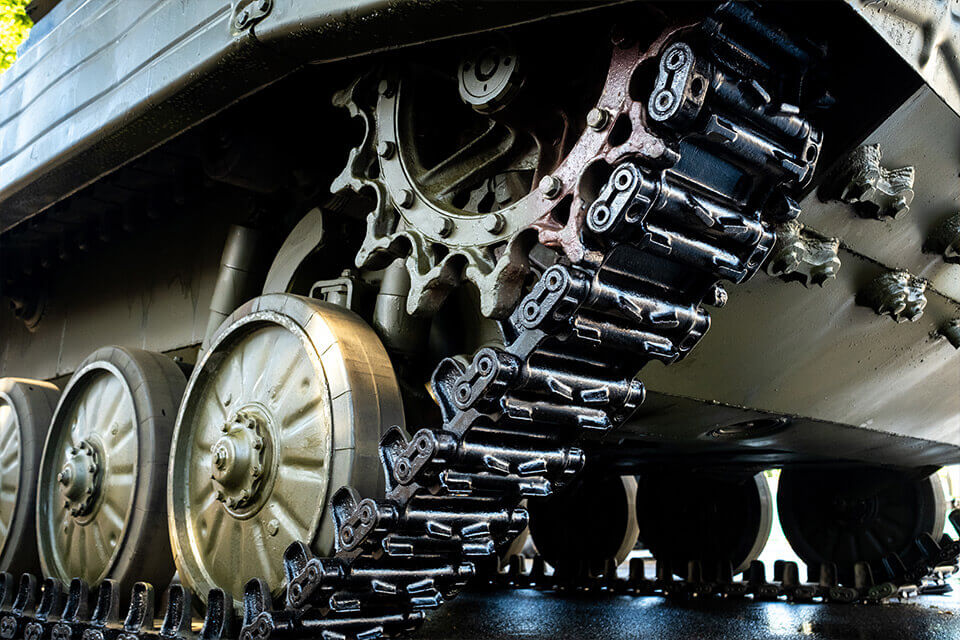

This applies to both Bundeswehr agencies and civilian companies. In defense technology, a distinction is made between heavy and light equipment. The heavy equipment includes, for example, tanks and the light equipment includes, for example, pistols.

DIN 2303 regulates the quality requirements for welding and related processes in the field of defense technology. The manufacturing companies that produce defense technology products therefore need a manufacturer qualification certificate.

What is a defense technology product?

Use in the military sector

Defense-related products include assemblies and components that are in the development, procurement and/or use phase and are intended for basic operation and/or use in the military sector.

Manufacturer qualification classes

Q1 to Q4

According to DIN 2303, the qualification of manufacturers is divided into classes. There are also classes Q1 to Q4. The materials from which the defense technology products are manufactured are classified according to their processing conditions (classes Q1 – Q3) or their product-related suitability for use (Q3 – Q4).

Overview Q1 to Q4:

Q1 – General requirements

This includes weir material made from commonly standardized materials

Q2 – Special requirements

Class Q2 includes liquid-quenched and tempered steels (HY 80, HY 100), non-magnetizable austenitic steels (1.3964) and AlZnMg alloys

Q3 – Armor function

Q3 includes armoring materials that fulfill the function of armoring the material

Q4 – airworthiness

Q4 Materials includes defense materials made from special materials used in the LfzT

Operating equipment and personnel

It all depends on the qualification

As one of the leading contract manufacturers for metal processing, we invest in modern production facilities and highly trained personnel. This enables us to manufacture even very sophisticated and complex welded assemblies. We use certified welders and welding supervisors who are qualified in accordance with DIN 2303. We also offer you comprehensive services as a contract manufacturer that are specially tailored to the requirements of military technology. Feel free to contact us!

Service from A to Z

Vertical integration as a decisive advantage

We also offer mechanical processing of your components so that the product meets the demanding military standards and ensures a perfect fit and functionality. Our service also includes painting, which provides protection, using high-quality paints and coatings. This gives you high-quality, durable and corrosion-resistant products.

Punctual and reliable delivery is our priority, we guarantee on-time delivery of your components. You can rely on our experience and expertise.

As a manufacturer, we can prove that we are qualified to produce the components for military use and that the processes meet the high quality and safety standards.