CONTRACT MANUFACTURER FOR TURNED PARTS

As a supplier of CNC turned parts, we specialise in machining.

We offer you a full service around your turned parts, including non-disclosure agreements (NDA’s), documentation, quality assurance and logistics services.

We manufacture turned parts for you as

- Prototypes, individual turned parts and special productions

- Small series up to 1,000 pieces/a

- Medium series up to 30,000 pieces/a

Our service as a manufacturer of turned parts

- Call orders & contracts

- Just-in-time deliveries

- External warehousing & reliable logistics

What are precision turned parts?

We deliver precision. Since 1869.

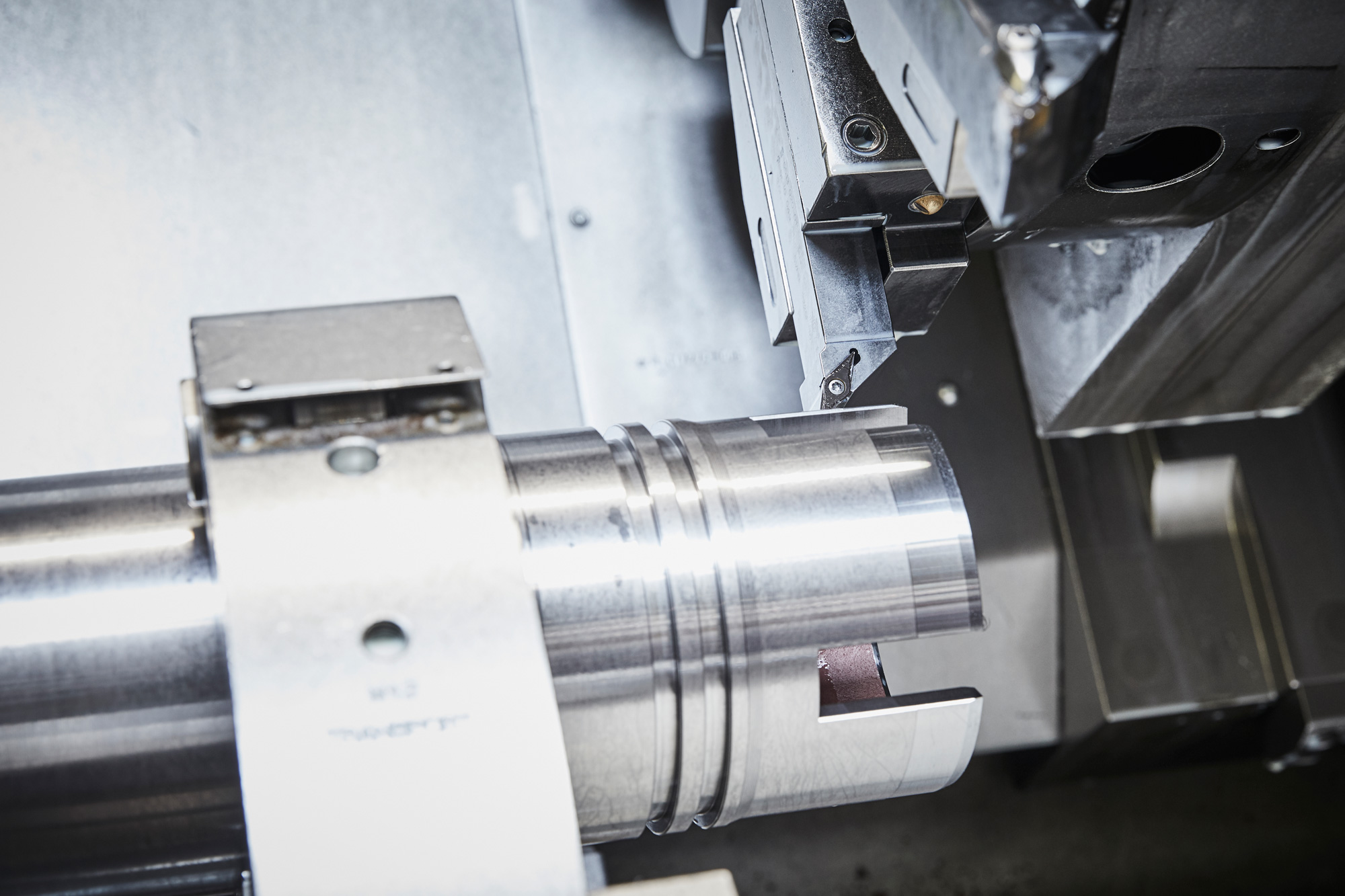

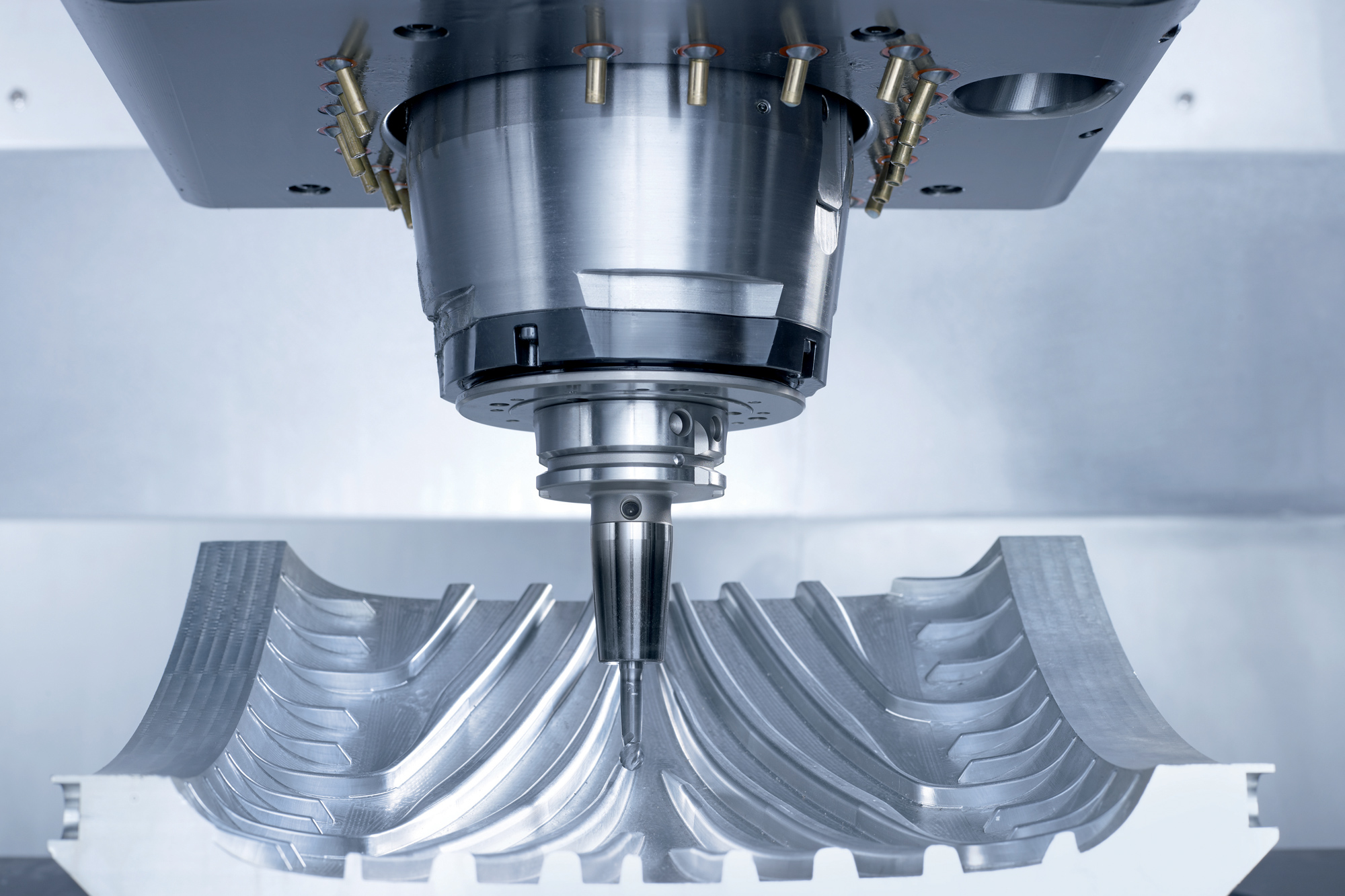

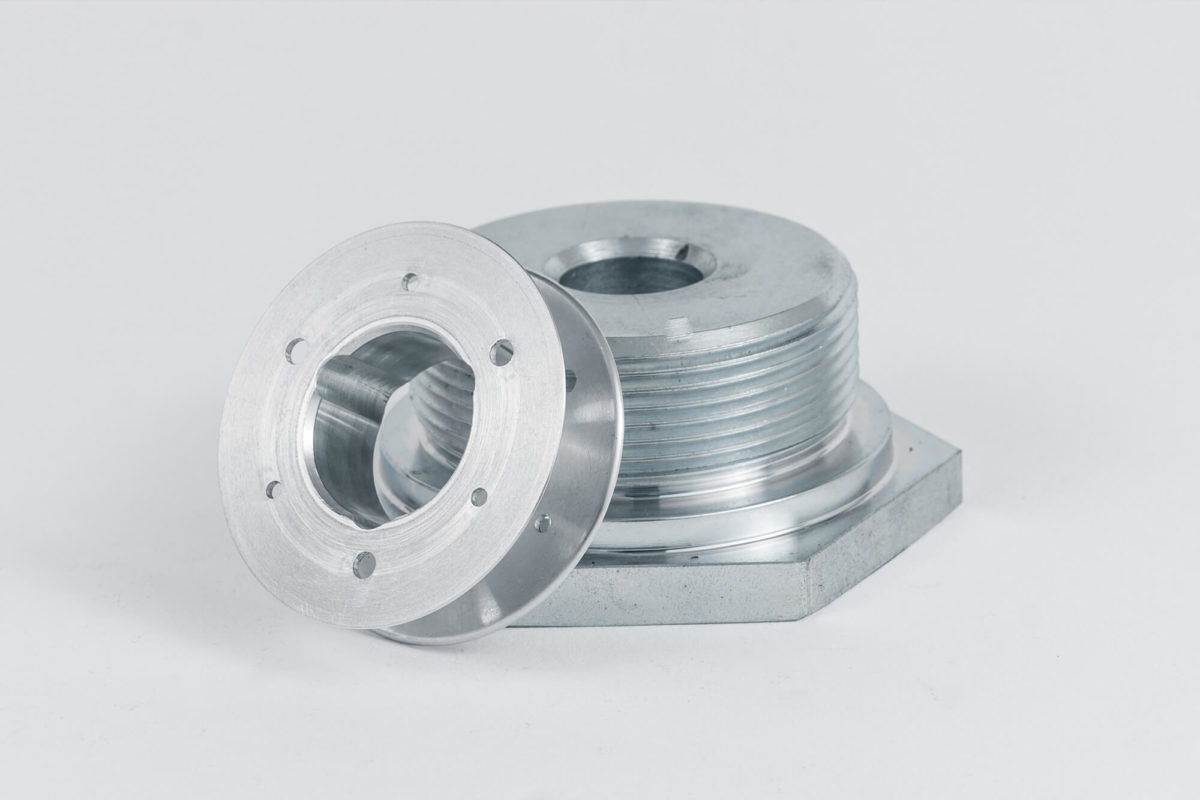

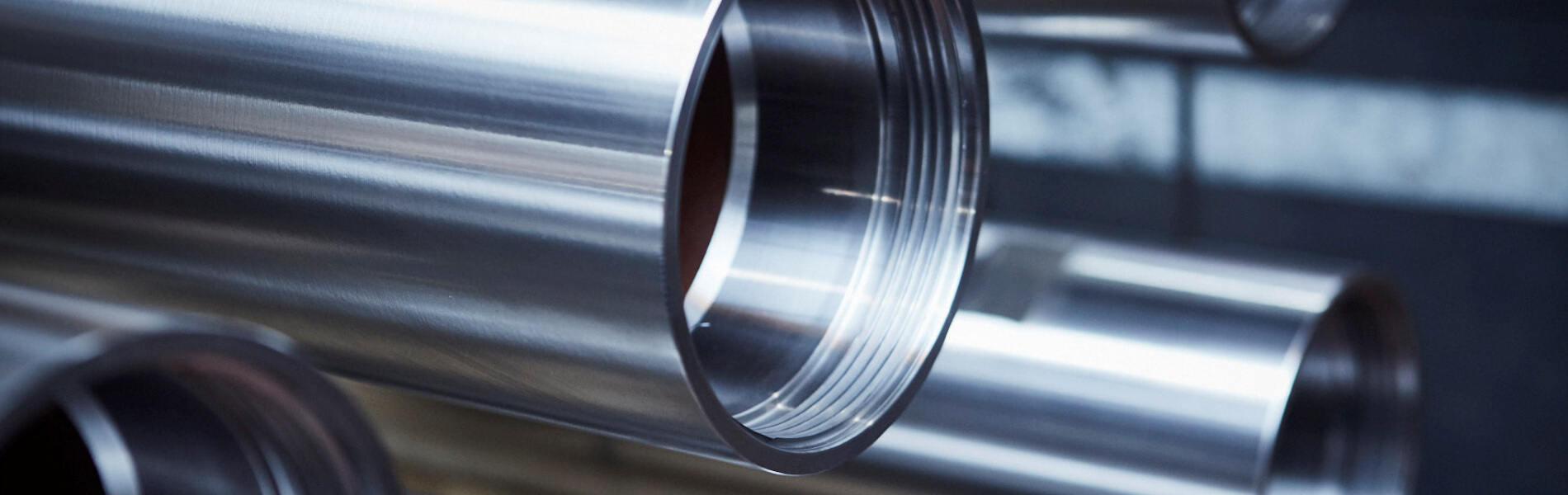

Turned parts that are manufactured very accurately or precisely are called precision turned parts. As a supplier for machining, we manufacture these precision turned parts using the turning production process. In accordance with your requirements, it is possible to maintain tolerances of less than 0.02 mm for turned parts. You can find more information about precision parts here.

Where are the turned parts used?

Areas of application for turned parts

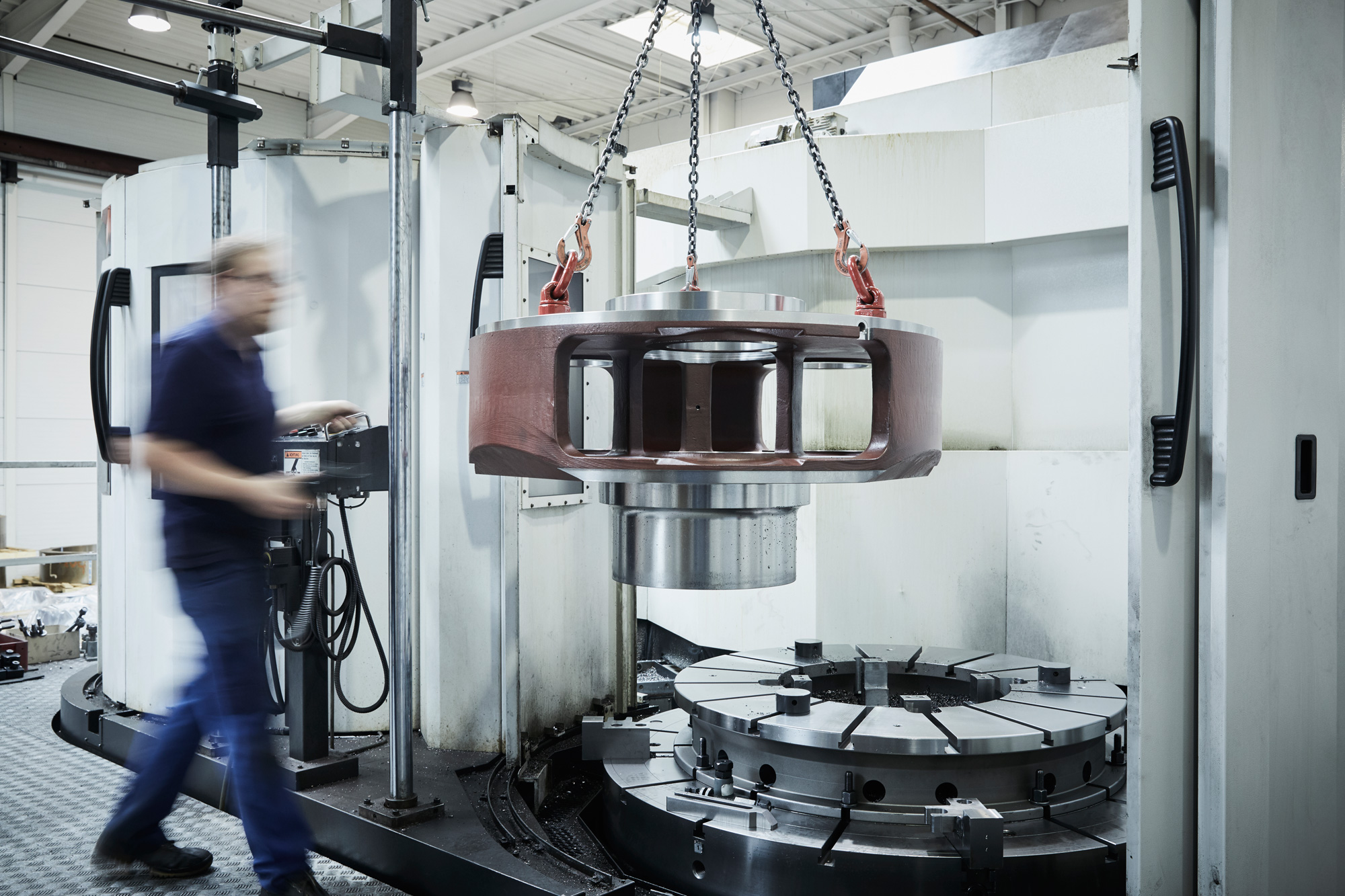

Turned parts are often components and parts of machines. Therefore, turned parts are used in all branches of mechanical and plant engineering. With state-of-the-art turning and machining equipment, we are able to offer you leading quality at an absolutely competitive price. Test us now and send us your enquiry for turned parts!

Which types of turned parts exist?

Learn more about the different turned parts

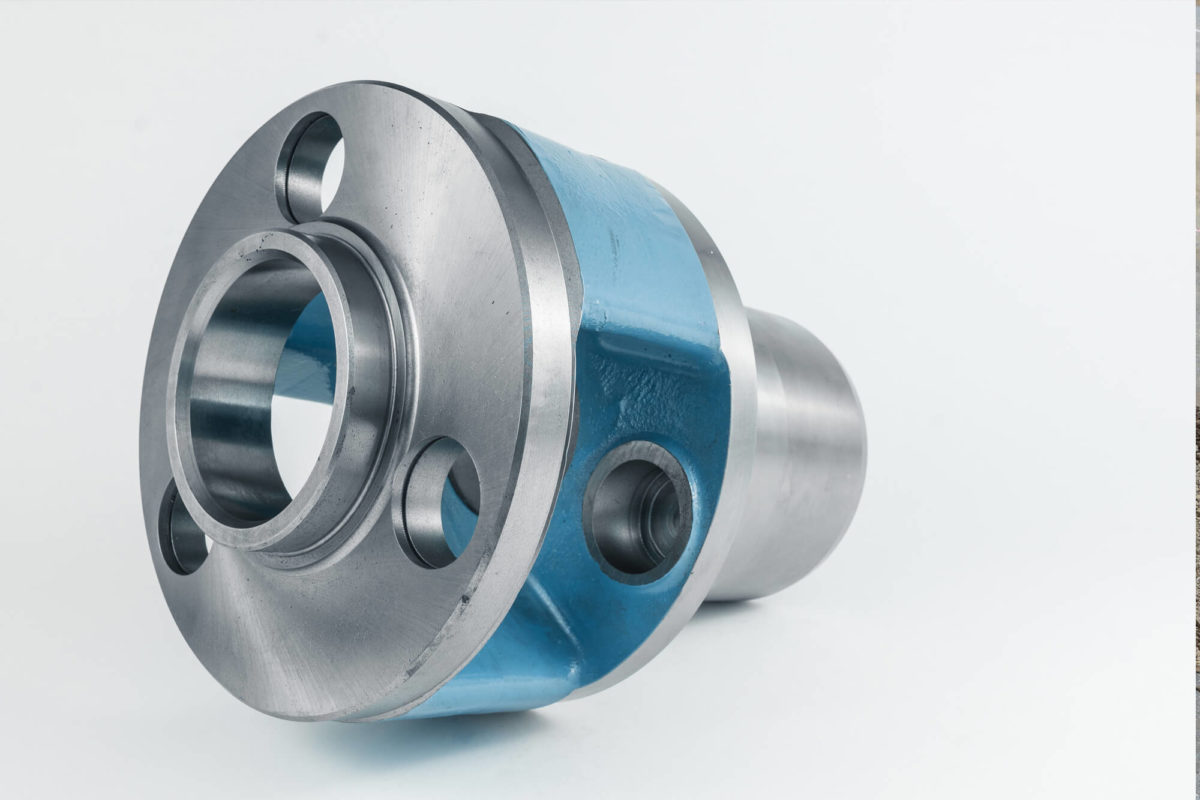

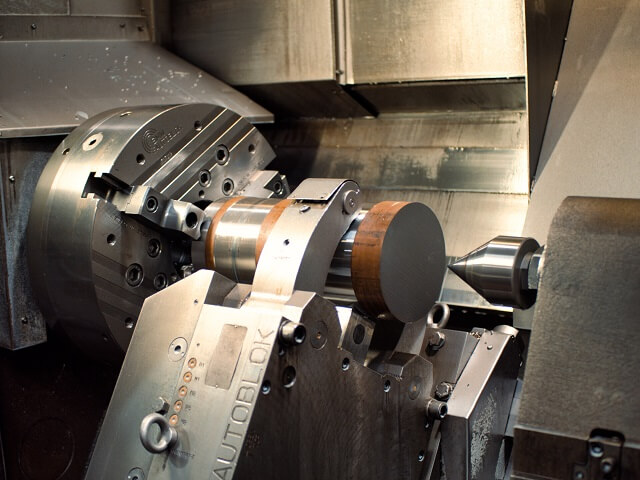

Chuck parts are turned parts where the diameter equals approximately the length. Chuck parts are clamped in lathe chucks for machining.

Shaft parts are turned parts that bend under their own weight. The imbalances and machining forces when machining shaft turned parts are comparatively higher and stronger than for chuck parts. Therefore, they are better supported during turning. The length of the shaft parts is a multiple of the diameter.

Rodparts are turned parts whose diameter is approximately the same as the workpiece and whose length is a multiple of that. The bars are usually fed to the lathe with the bar loader. After machining a workpiece, it is separated from the material bar with cut-off turning. The bar is then fed further into the lathe so a further workpiece can be made from it.

Lace parts are clamped between the tips and turned.

Which materials are suitable for turning?

From easy to difficult to machine

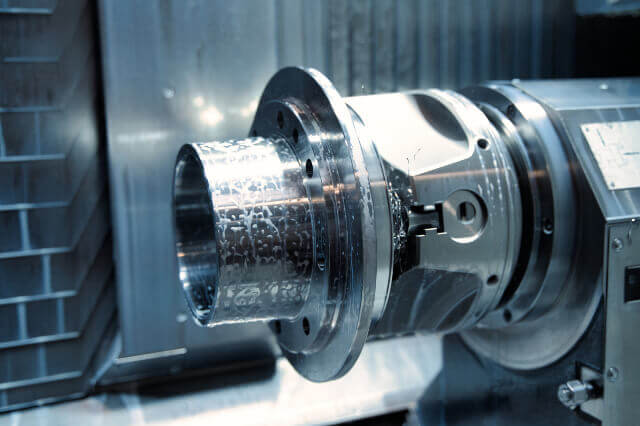

Depending on the customer’s requirements, almost all types of metals are used for turning. These can be categorised into materials that are easy to machine and materials that are difficult to machine. As your competent contract manufacturer for turned parts, we offer you the production of turned parts in both material categories.

The most frequently used materials include all types of steel, stainless steels, aluminium, copper and many more. We turn and machine special materials such as titanium or composite materials using special turning tools. We will be happy to advise you personally on the optimal turning of your materials. Please feel free to contact us!

What does CNC turning mean?

Our manufacturing possibilities

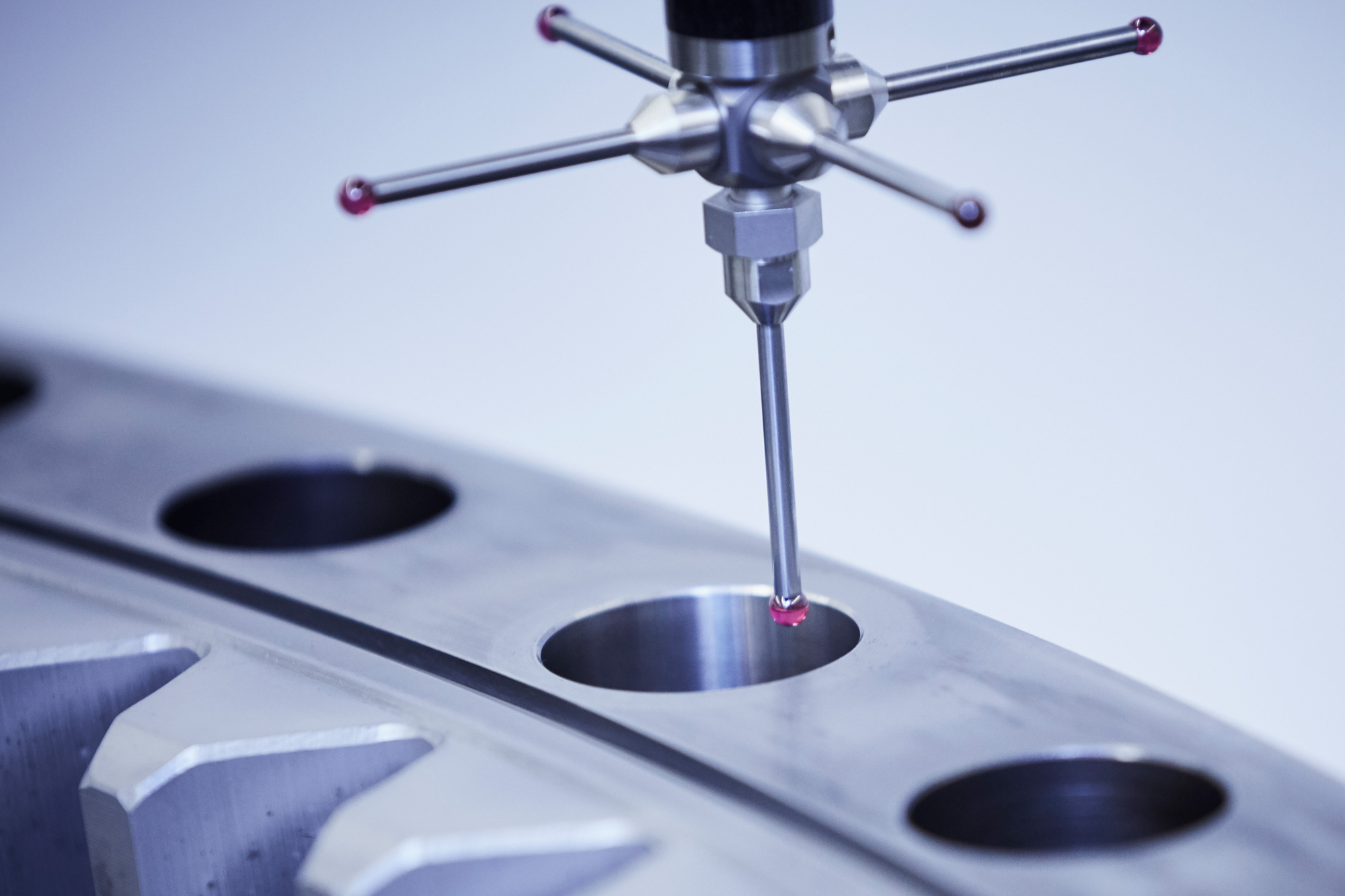

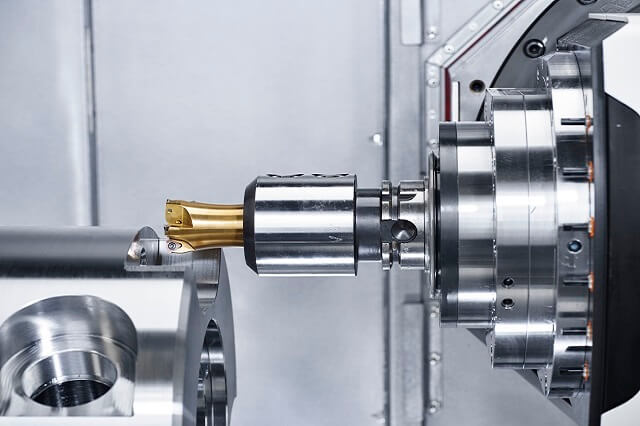

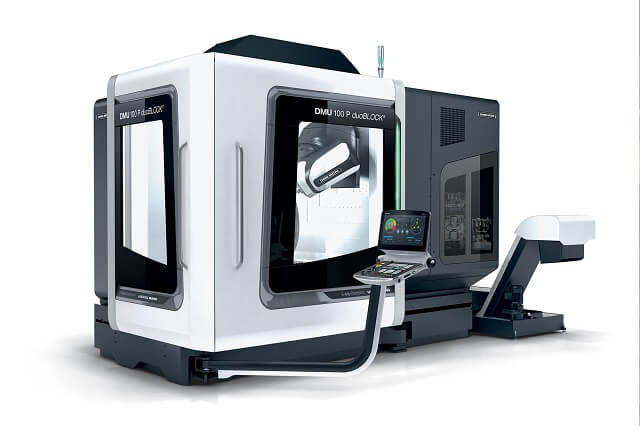

CNC turning is the computer-aided manufacturing process for turning parts. CNC stands for “Computerized Numerical Control”. The components are individually programmed. With this production programme, the lathes can then automatically produce the CNC turned parts. The machining process is monitored by sensors on the lathe and by the highly skilled machinist. By means of CNC turning, it is possible to produce turned parts even in very large series with very consistent quality. For quality assurance, we also use 3D measurement for components.

request machine listTurned parts contract manufacturing

SPALECK – Your No. 1 supplier

We offer you the complete range of machining and metal processing from a single source. We would be pleased to invite you to visit us at our headquarters in Bocholt and our other CNC production site in Greiz. We are sure we will find many opportunities for cooperation together.