Use case

Classification of difficult-to-screen, sticky and moist materials

Materials for separating cuts from approx. 0.2 to 120 mm.

With our 3D combi, you invest in efficiency. Thanks to this “2-in-1 solution”, you save money, steel construction and space requirements. After installation, the 3D combi impresses with outstanding, consistently high screening results and impressive performance.

Screening technology must not only function optimally.

It also has to do a great job for the subsequent processing steps during recycling – just like your new SPALECK 3D combi.

We develop and produce high-performance and absolutely reliable high technology for screening for our customers.

The SPALECK 3D combi screening machine sets the global standard for profitable processing and recycling.

Classification of difficult-to-screen, sticky and moist materials

Materials for separating cuts from approx. 0.2 to 120 mm.

Recycling materials of all kinds, such as

MV slag, shredder light fraction, shredder heavy fraction,

Scrap metal, electronic scrap, mixed construction site waste,

Household, commercial, bulky waste, compost,

Plastic fractions, biomass, …

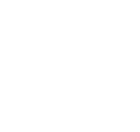

The design combination ensures optimum loosening and circulation of the product in the upper deck. Even coarse-grained material can be screened on a screening machine with a flip-flow screen deck.

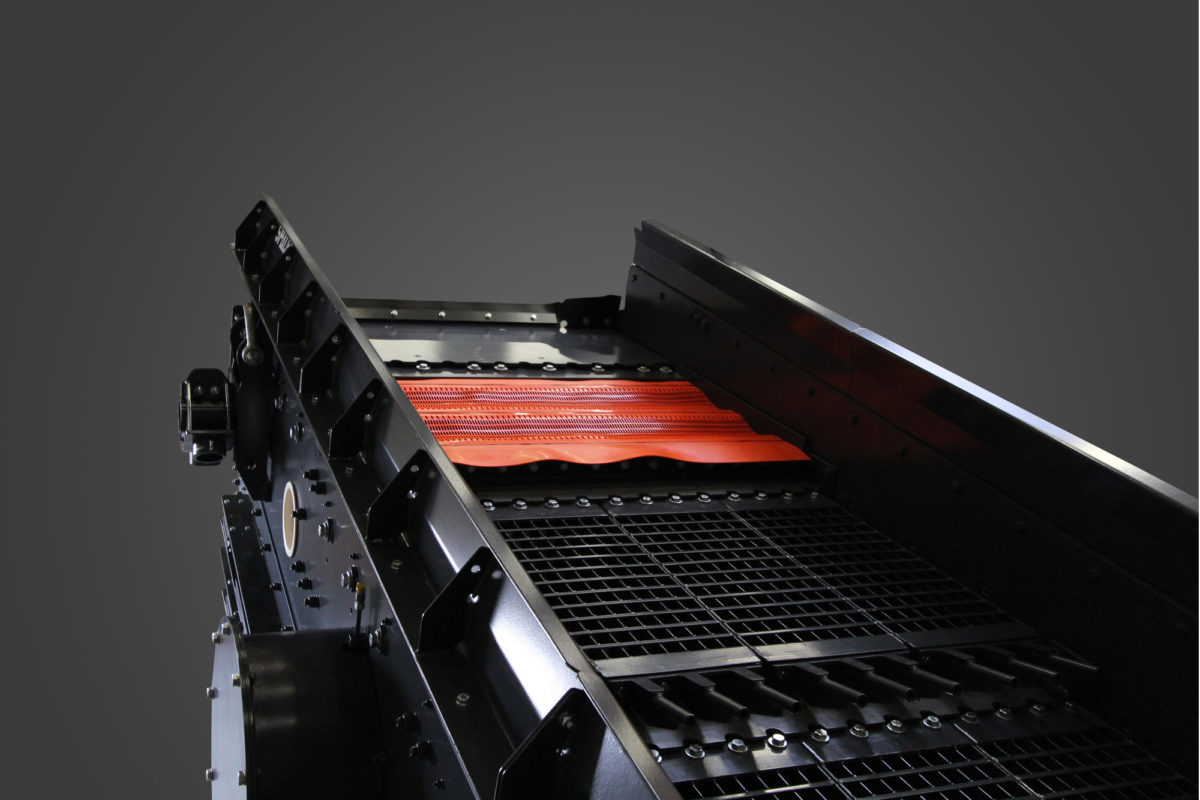

The screen deck with 3D screen segments arranged in a cascade above the flip-flow screen deck protects and relieves the flip-flow screen mats. Your service life is increased and guarantees optimum screening results.

The 3D screen segments with maximum open screen surface are quick and easy to change thanks to the modular design. The screen mats of the flip-flow screen deck are fastened without screws and without interfering edges. This enables quick replacement of the screen mats and an optimum product flow on the screen surfaces.

This vibrating screen is designed as a circular vibrating screen and is driven by an unbalanced shaft drive with a standard three-phase AC motor.

The counter-swing frame neutralizes residual vibrations.

The stationary or alternatively swinging cover can be opened without tools and ensures quick and easy access to the screen segments.

Open this in UX Builder to add and edit content

SPALECK flip-flow screens set the standard worldwide in terms of economy, reliability and efficiency.

Separation with experience. Separation with experience. Terex Finlay and Powerscreen, leading international suppliers of mobile processing technology, rely on SPALECK expansion shaft technology for screening.

MoreWe build our SPALECK flip-flow screens in such a way that you can reprocess and recycle them in the best possible way.

This means that you minimize your maintenance and cleaning costs with flip-flow screens from SPALECK. At the same time, your employees can easily adjust the screening machine optimally to the respective screening material.

Are your screenings particularly sticky and sticky? Fine! With our patented, easily retrofittable expansion shaft cassette, your screen linings will still stay clean!

SPALECK offers you many smart solutions for screening. Like our patented MultiZONE deck, for example. This provides you with several screening areas on one screening deck. This allows you to easily control the screen quality and flexibly adapt your screen to a wide variety of material flows.

Your screen material may change.

That’s why we have hundreds of different customized screen surfaces available for you and your applications.

Changing them by your employees is quick and easy.