BEST SCREENING. BEST SORTING.

Skrotfrag sets new standards in the recycling of non-ferrous metals with SPALECK ActiveFEED and screening technology

In Sjövik, the Skrotfrag Group operates one of the three largest recycling plants for non-ferrous metal processing in Europe

Reine Bergquist (left), Per Ola Berthelsen (right): “The continuous material infeed of the ActiveFEED and the precise separation by the SPALECK 3D COMBI guarantee the highest purity in our target fractions“

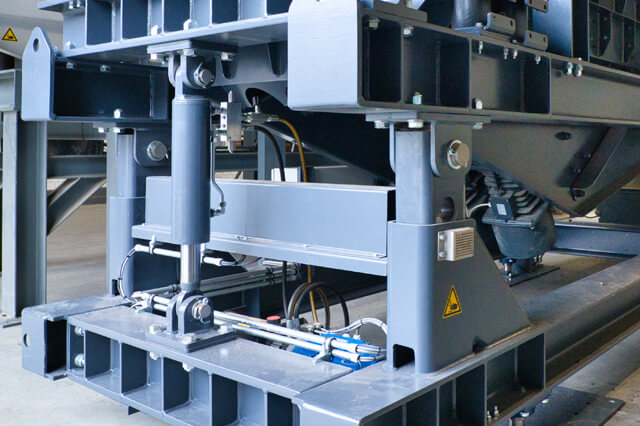

Most modern technology for NF metal processing – Skrotfrag relies on SPALECK for material infeed and Screening

“Our NF metal processing starts with the SPALECK screen. We classify our input material cleanly into the screen fractions 0 – 5 mm, 5 – 20 mm, 20 – 60 mm, 60 – 120 mm and the oversize > 120 mm.“

“With the ActiveFEED, we can keep the infeed for our sorting technology absolutely continuously and optimise the sorting quality.“

Very clean screening results: The 0 – 5 mm screening fraction of the SPALECK 3D COMBI screen