APPLICATION

Screening with a hole diameter of approx. 20 to 300 mm

Your new SPALECK recycling waste screen is your partner that you can use to increase your recycling process to a new performance level.

More performance, even more flexible and more economical. Outstanding technology.

MADE IN GERMANY. SINCE 1869.

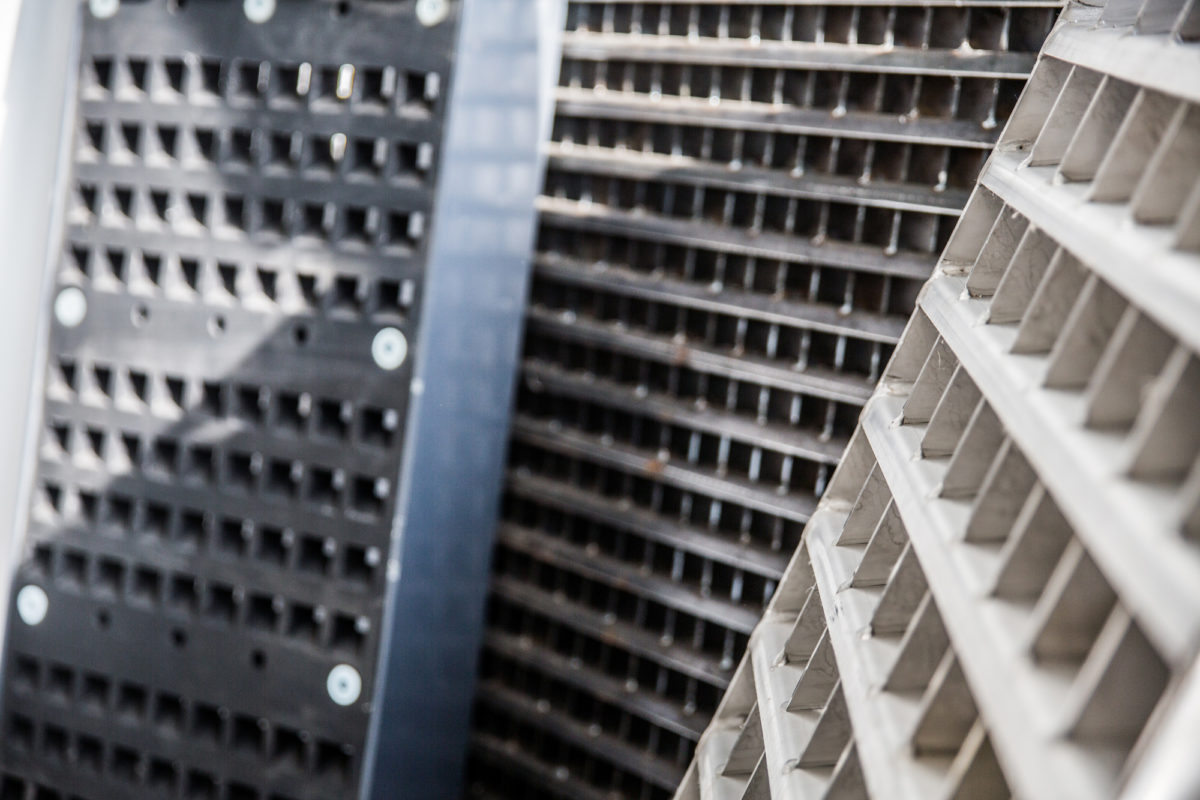

We design our screening machines so that you can use it to recycle optimally and earn money. Our recycling waste screens also offer you the greatest possible open screen surfaces. In this way, you achieve the highest screening performance with maximum screening quality.

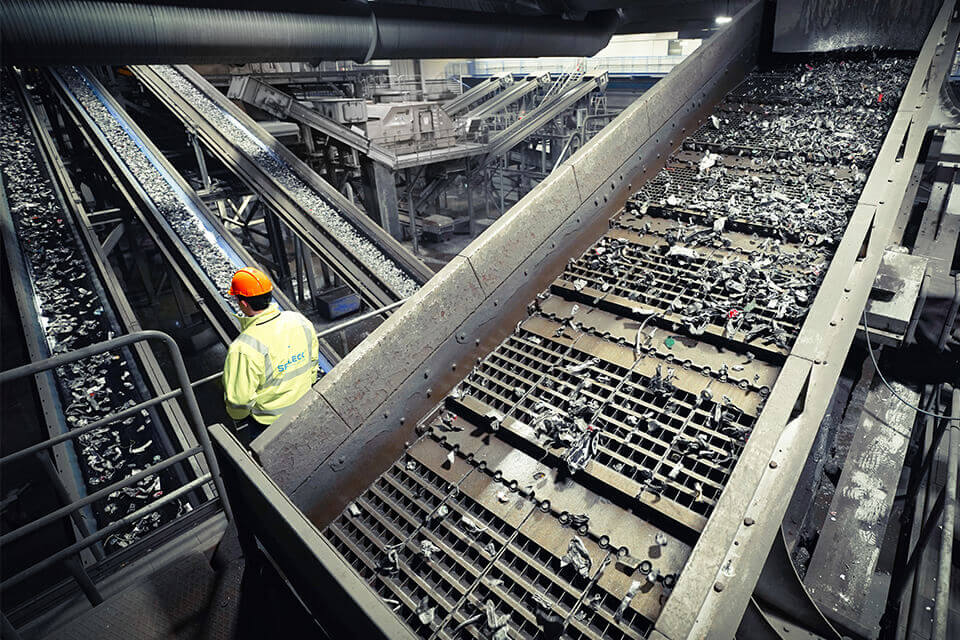

Being a screen machine manufacturer, we know we know what counts most for you. Screening performance, screening quality and absolute reliability when screening and recycling. Our screening machines fulfill these requirements: Efficient and reliable. In this way, they can easily be integrated into your recycling system and MRF, for example.

Screening with a hole diameter of approx. 20 to 300 mm

All types of recycling materials such as, e.g. domestic, industrial and bulky waste, wrappings, biomass, matured timber, old tires, electronic waste, roofing paper, shredder material, building rubble, mixed construction site waste, metal, etc.

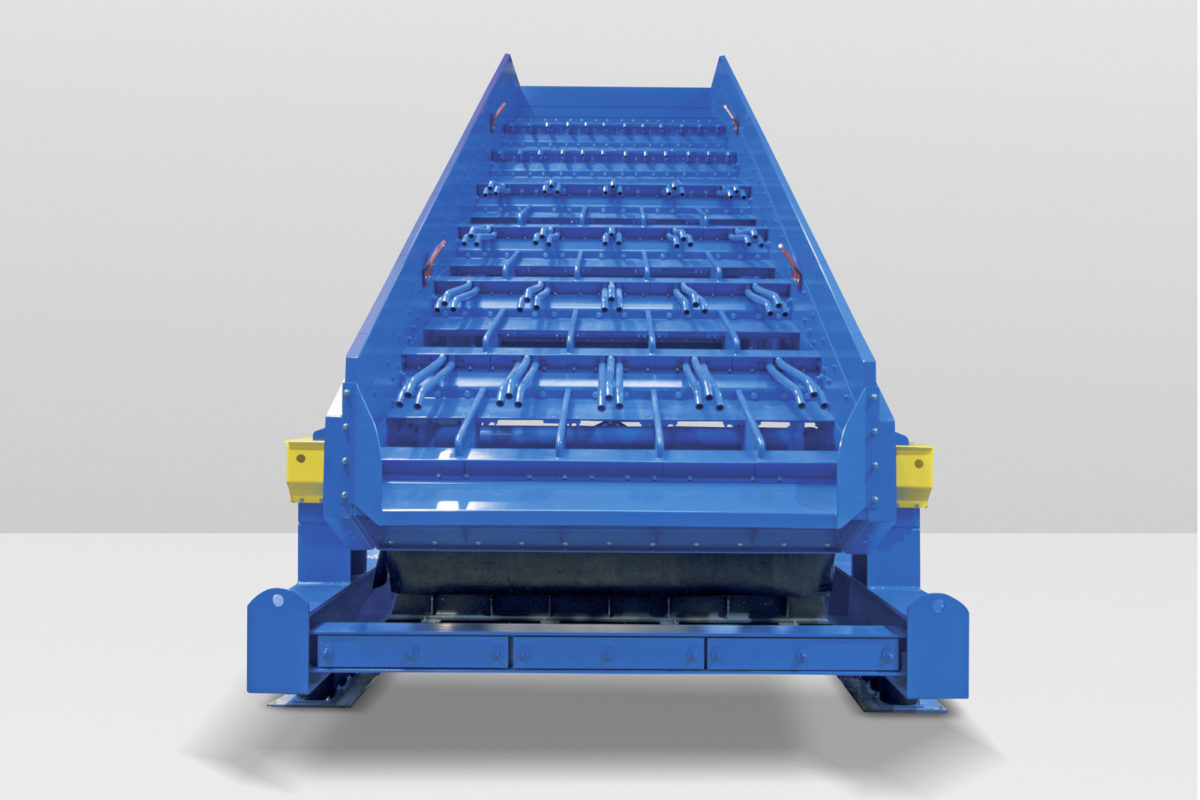

The Spaleck recycling waste screen is carried out as a vibrating screen with a circular motion and is driven by a high-performance and equally energy efficient three-phase AC motor.

The blind bottom on the infeed side guarantees an efficient utilization of the screening surface, a good material flow, increases the service life of the screening elements and reduces blocking material.

The screening elements can be changed easily and quickly and are therefore easy to adjust to the different sized cuttings.

The sub-frame compensates the residual vibrations of the screen. The optional cover can be opened without using tools and ensures quick access to the screening module.

An almost blockage-free screening procedure, also with very different screening material.

Very pure screening fractions and the highest screening quality

Minimum effort for cleaning with very good accessibility

High screening performance thanks to the greatest possible open screening surfaces

Very low operating costs and maximum machine availability

Worldwide, our SPALECK screening technology sets new benchmarks for reliability and efficiency when recycling and screening.

Separation with experience. Separation with experience. When screening, Terex Finlay and Powerscreen, leading international suppliers of mobile recycling technology use the SPALECK screening technology.

more

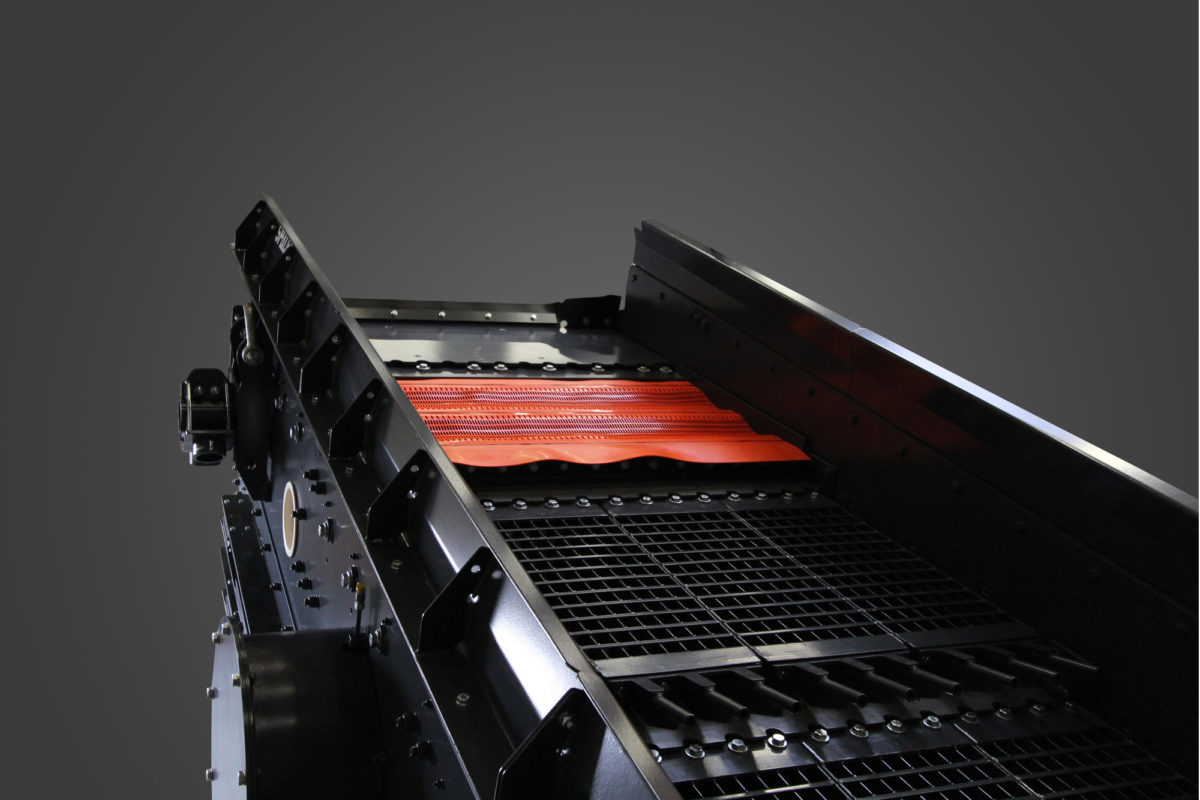

Your material is particularly sticky and caking? Fine! With our patented easily retrofitted Flip-Flow cassette, your screening layers will still stay clean!

With us, you are not buying from the shelf. We offer you the best screening machine for your material. In this way, you can be reassured that you can screen your material and recycle in the best manner. Try us out! With a screen test in the SPALECK TestCenter, you can already see the optimum screening results before a possible order.

Your screening material can change.

For this purpose, we keep hundreds of different customized screening elements ready for you and your applications.

Your employees can change them quickly and easily.